More About

Swastik Industries India

In 2002, the company’s expansion extended to Middle East in its first successful bid in the overseas market with Locomotive customers- BFG international Bahrain. After the successful entry in the Global market company continued a strong growth pattern and expended its overseas customer base to the FRP industries, Locomotive (Railway) industries, Automotive industries & construction industries such as Kirby Building Systems,Kuwait and Ras-Al-Kamiah, Zemetra and Chemparts.

Growth in the fabrication, casting & machining For the Domestic as well as overseas market in the 2007s prompted SWASTIK INDUSTRIES to invest $1 million in a new plant at Vasai Mumbai.

As of today, the turnover of our company is approximately $1 million the infrastructure of our factory workspace expands to 12,000 sq. ft. With well-versed machineries, skilled manpower setup and experienced staff and workers (50) at Vasai who are experts in Fabrication work all types of ferrous and nonferrous Metals.

Growth in the fabrication, casting & machining For the Domestic as well as overseas market in the 2007s prompted SWASTIK INDUSTRIES to invest $1 million in a new plant at Vasai Mumbai.

As of today, the turnover of our company is approximately $1 million the infrastructure of our factory workspace expands to 12,000 sq. ft. With well-versed machineries, skilled manpower setup and experienced staff and workers (50) at Vasai who are experts in Fabrication work all types of ferrous and nonferrous Metals.

SWI in new Millennium:

Domestic Market

SWI today manufactures structural fabrication as well as simple fabrication jobs for corporate houses, industrial sheds, and other commercial buildings Malls & Hotels,Petrol pumps. This job includes from simple fabrication to typical fabrication of fancy items like front space, canopy etc. Fabrication of staircase, railings, structural floors, parabola ,screens, fancy gates etc. is done at site.

International Market

SWI today manufactures structural fabrication as well as simple fabrication jobs for Locomotive- Railway Industries for Middle east as well as for Europe. M/s. Swastik Industries maintain a steady growth rate since its inception in 1987 and heading for an ambitious capacity expansion in the near future.

.

.

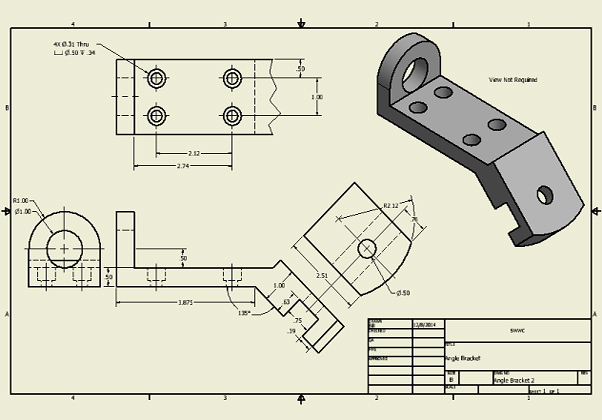

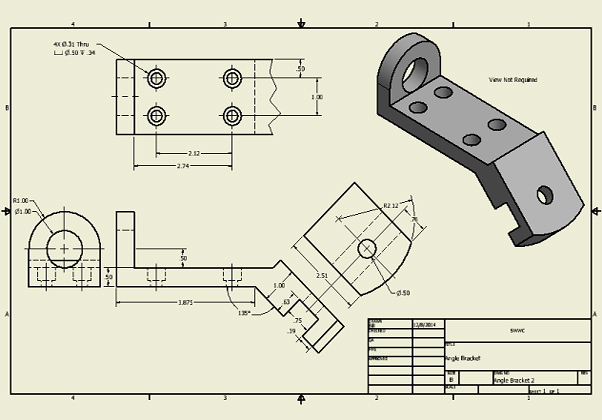

Design Concepts to High-Volume Production

With a 20-year history of providing quality metal parts, the SWASTIK Group of companies is a recognized industry leader in a wide range of metal fabrication processes. In addition to stamping and forming, the SWASTIK Group’s capabilities also include CNC machining, wire EDM and Metal Injection Moulding (MIM)

Our various metal forming and production processes allow us to produce prototype and short-run jobs, and to make the transition to high volume production. The manufacturing staff works closely with engineering and quality assurance personnel to produce consistent high-quality parts. SWI is backed up with latest automated design capabilities for tooling & our technical staff will design and implement the most cost effective manufacturing method for your program both in the short and long term.

Our various metal forming and production processes allow us to produce prototype and short-run jobs, and to make the transition to high volume production. The manufacturing staff works closely with engineering and quality assurance personnel to produce consistent high-quality parts. SWI is backed up with latest automated design capabilities for tooling & our technical staff will design and implement the most cost effective manufacturing method for your program both in the short and long term.

Our CAD software portfolio includes

Auto CAD, Bob CAD, Master Cam, Solid Works